INOX OVERVIEW

WHAT IS INOX?

Inox – or stainless steel, also known as stainless steel (stainless steel) is a steel alloy. It is a form of steel made by mixing molten iron with molten chromium and certain other metals and non-metals.

Stainless steel consists of about 10.5% chromium along with iron and other metals and non-metals. Other metallic elements present in stainless steel are nickel, molybdenum, titanium, and copper. Non-metallic additions are mainly composed of carbon (about 1.2%).

The most prominent stainless steel is its resistance to corrosion. The higher the chromium content, the higher the corrosion resistance. Stainless steel’s resistance to corrosion and staining, low maintenance and a familiar luster make it the ideal material for many applications that require both steel strength and corrosion resistance.

CLASSIFICATION AND APPLICATION OF INOX

The types of stainless steel on the market today include: Stainless Steel 304, Inox 430, Inox 202, Inox 201, Inox 316. However, the 3 most commonly used types are 304, 430 and 201:

-

Stainless steel 304

The composition contains 18% Chromium – 10% Nickel. Stainless steel 304 belongs to the Austenitic group – known as non-magnetic steel. This is a non-magnetic stainless steel that can be used in any environment. This type of stainless steel is flexible, malleable, easy to weld, especially very safe in contact with food. Therefore, the price of the product is quite high and it is popular to use.

This type is widely used to make household appliances, containers, industrial pipes, industrial ships, architectural outer shells, other construction works…

-

Stainless steel 201

The composition contains 18% Chromium – 8% Nickel. This type of stainless steel also belongs to the Austenitic group – non-magnetic, durable over time. However, during use, it is necessary to avoid direct contact with acids or salts. The price of the product is not too high.

Compared with 304, stainless steel 201 is harder, but more susceptible to corrosion. The surface is also not as shiny as 304 stainless steel. However, the durability of stainless steel 201 is quite high. This is one of the strengths of stainless steel 201. Stainless steel 201 is a material that is easy to process because of its good formability. Machining methods such as cutting or welding can be performed on this type of stainless steel.

-

Stainless steel 430

Contains 18% Chromium – nickel free. This type of stainless steel belongs to the Ferritic group. Stainless steel 430 has the lowest quality among the above stainless steels. This type of stainless steel is magnetic, easily affected by the surrounding environment, easy to break, making the product tarnished, no longer shiny. The advantage is that the price of the product is quite cheap.

The common applications of stainless steel 430, especially “stainless steel plates”, are widely used in parts in household electrical appliances (refrigerators, televisions, washing machines …) kitchen appliances (pots, sinks, pots, etc.) pans, spoons, forks, etc.), decorative objects in the house… One of the most common uses of stainless steel 430 is to be used to make pans/pots used for induction cookers thanks to its unique magnetic ability.

SO, DOES INOX GET RUSTED?

The answer is YES.

Although stainless steel is more resistant to corrosion and oxidation than other carbon steels and metals. But in some special environments, beyond the protection threshold of stainless steel, it will be oxidized. In addition, physical impacts affecting the stainless steel surface will further damage the protective layer on the stainless steel surface (chromium oxide). Thereby making stainless steel easier to oxidize faster.

Stainless steel is only relatively stable in oxidizing conditions, and conversely if it is in non-oxidizing conditions, it will not be stable anymore. In particular, it can withstand the corrosion of concentrated sulfuric acid and concentrated nitric acid, but not the corrosion of non-oxidizing acids such as hydrochloric acid, dilute sulfuric acid.

In addition, stainless steel is not susceptible to corrosion thanks to the chromium content in the compound that composes it, so thanks to the ratio of chromium and other elements in stainless steel and the heat treatment process during processing Whether the work is appropriate or not will directly determine the corrosion resistance of stainless steel. Therefore, whether stainless steel will rust, the answer is that stainless steel does not rust, but it is not absolute, in special conditions it will also rust.

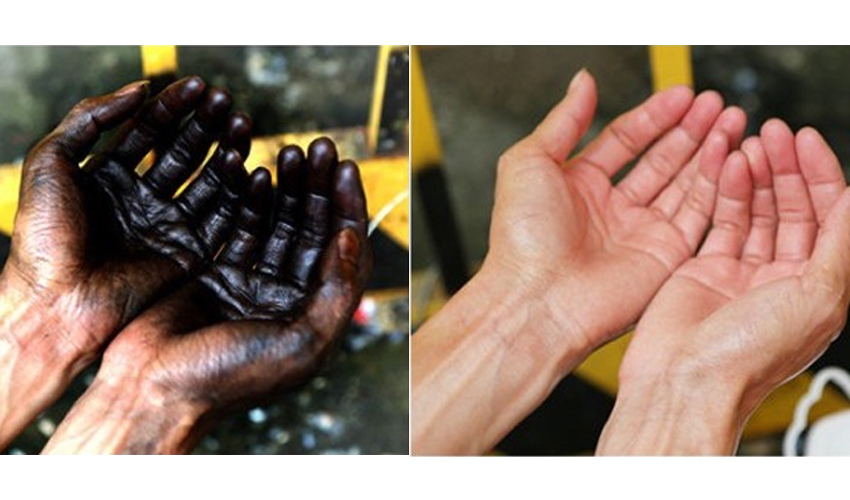

HANDLING METHODS

PHYSICAL/MECHANICAL METHODS

You can use items such as dishcloths, towels to scrub the rust site. This method can quickly remove the rust layer on the stainless steel surface. But this method only applies to light rust stains, and this method will also harm the surface of our items. From there, the surface of the item will be easily rusted again, even heavier than before.

CHEMICAL METHODS

There are many methods of using chemicals to clean rust stains on stainless steel surfaces. Among the simple ways can be mentioned such as:

- Using the product REN H510

REN H510 is a product that removes limescale deposits, rust, cooking oil, grease and stubborn stains on stainless steel and aluminum surfaces.

Usage: Dry the surface to be cleaned. Apply REN H510 directly by spraying a thin layer of product. Wait a few minutes for the product to work on this layer of rust. Then rinse off with water. The advantage of this method is that there is no need to physically damage the surface of the device.

>>> See more cleaning products to refresh stainless steel and aluminum REN H510

- Use carbonated water

Carbonated water is no stranger to us (coca cola, pepsi, 7up,…) These carbonated drinks usually contain a certain amount of phosphoric acid. So using carbonated water is also a solution to remove rust on stainless steel effectively.

How to use: Pour carbonated drink directly on the surface of the device or can use the soaking method. Wait a few minutes, then rub the rust on the stainless steel, then rinse with clean water.

=>> Note: Soft items should be used to avoid damage to the surface.

- Use vinegar

Similar to carbonated drinks, vinegar also contains acetic acid – concentrations from 2% – 5%. Rust removal effect is similar to carbonated water. Alternatively, you can also use lemon and salt instead of vinegar.

How to use: Pour vinegar water directly on the surface of the device or you can use the soaking method. Wait a few minutes, then rub the rust on the stainless steel, then rinse with clean water.

- Baking soda

Baking soda is an inexpensive, easy-to-find ingredient. We have talked a lot about Baking soda and its uses. One of them is cleaning rust stains on the surface of items. You can completely use them to clean rust stains on stainless steel.

How to use: Mix baking soda with water or vinegar until a paste is formed. Pour this mixture over the rust site. Wait a few minutes, then rub the rust on the stainless steel, then rinse with clean water.

>>> See more: What is Baking Soda? Applications of Baking Soda