Grease is used to lubricate and cool, limit corrosion of components in machines. Industrial greases are greasy, they cannot clean themselves with water or conventional detergents. Instead, it is necessary to use specialized industrial degreasing chemicals to remove grease and dirt on the surface of the device. Here are some key information you should look at before using this chemical.

What are degreasing chemicals?

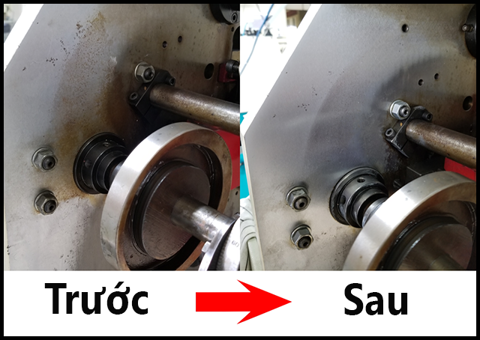

Industrial degreasing chemicals are chemicals currently commonly used in industrial production areas. Degreaser has the effect of cleaning machinery and equipment periodically. If you only use ordinary cleaning chemicals, it will not be possible to clean the sticky grease stains. In contrast, when using degreasing chemicals, it helps to clean quickly. Low cost and easy to use without disassembling parts but still easy to clean.

Principle of industrial degreasing

Industrial grease is a mixture of base oils and additives that lubricate machine parts. Contributing to increasing the life of machine parts, reducing the possibility of rust. In addition, degreasing chemicals clinging to metal surfaces can also separate the oil layer on the surface through chemical preparations. Conventional degreasing chemicals are divided into organic, inorganic, and alkaline chemicals. The mechanical details when using cleaning ensure the quality is significantly increased. Otherwise, grease and dirt will remain on the surface of the product. Unfavorably affects the brightness and gloss of the product.

With the increasing demand for use, many types of degreasing chemicals were born. When putting grease cleaning chemicals directly on metal surfaces to be degreased. At this time, a number of chemical reactions will take place. Grease clinging to metal surfaces reacts with chemicals, grease is removed from metal surfaces. Return the inherent beauty to metal surfaces. This is the general principle of degreasing chemicals.

Should you use industrial degreasing chemicals?

Thanks to the improvement of technology, more and more types of degreasing chemicals were born. Especially, there is a variety of prices for users to freely choose. However, users are still wondering whether to use degreasing chemicals or not? Because most are afraid of causing a corrosive reaction to the metal. This can directly affect the quality of the device.

Understanding that concern, manufacturers have not stopped researching. To market many safe industrial degreasing chemical products. Does not cause harmful reactions to machines and components. So, you can rest assured during use. Degreasing chemicals are also known for containing strong chemical ingredients. So they have the ability to quickly and effectively clean grease and sticky substances. Help users save a lot of time and effort.

See also: What is a surfactant? Classify

Advantages of specialized degreasing chemicals

In addition, these cleaning solutions also promise to bring many different advantages.

- Non-flammable, non-caustic, non-toxic, non-volatile and highly degradable.

- Chemicals have the ability to quickly clean all grease stains on different surfaces. Soluble in both soft and hard water. Safer when in contact with many different material surfaces such as Formica, aluminum, wooden furniture.

- The ability to effectively clean even the most stubborn grease stains. Make sure not to leave a greasy film after cleaning.

- Use degreasing chemicals to effectively remove grease, stains from tools, walls, floors, vehicle frames, chassis, engines, pipes, etc. Even other industrial surfaces.

Benefits of industrial degreasing chemicals

Industrial degreasing chemicals are now commonly used in the manufacturing to manufacturing industries. Thanks to the benefits they bring. The cleaning of industrial greases during production is extremely important.

For machines, grease production lines stick longer. They cause blockages, difficult operation not like new. Degreasing chemicals will remove the old layer of grease, thereby helping to refresh the metal machinery system. Contribute to a more efficient production process. For equipment from aluminum, the metal in the manufacturing process will have grease and oil that will make the device look unattractive. The use of degreasing chemicals saves time and is faster than conventional methods.

In addition, industrial degreasing chemicals also help you save a considerable amount of money. During the maintenance of metal machinery. With a short time but still ensure to bring high results as desired.

How to choose a good industrial degreasing chemical?

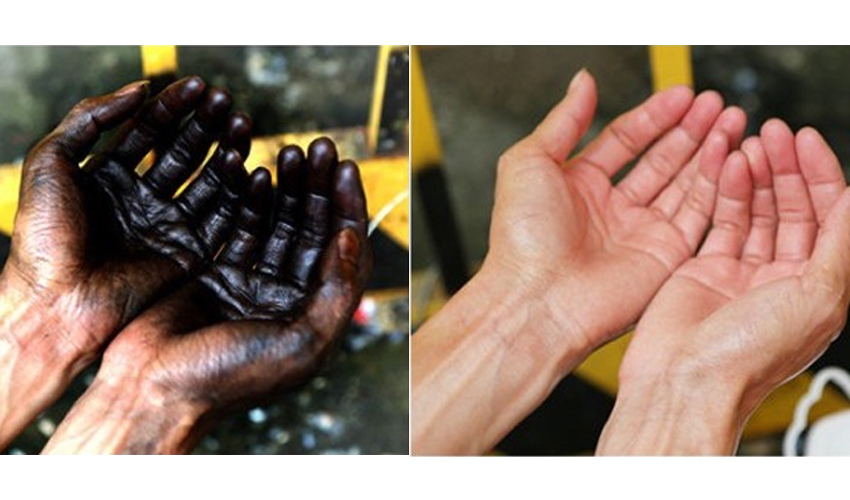

Industrial degreasing chemicals bring a lot of benefits to users. In particular, they have low cost but high efficiency. However, the selection needs to be carefully considered to choose the right chemical for the surface to be cleaned. Avoid causing corrosion problems as well as being user friendly. Because in the cleaning process must soak in chemicals for a certain period of time. If chemicals have health effects, they will have adverse effects on people who use them.

Industrial degreasers have greasy, sticky properties that are difficult to remove these substances. Therefore, grease cleaning chemicals are usually alkaline substances. They help remove the grease. The stronger the adhesive, the longer it takes to stain. So it will be difficult to clean, requiring strong chemicals, which will also affect the person in contact. Therefore, during use, it is necessary to use protective equipment such as rubber boots, gloves to ensure more safety.

Notes to be aware of when using degreasers

In the process of using industrial degreasers, you should also pay attention to some important issues as follows. To ensure the safety of yourself and the equipment during the cleaning process.

Odorless degreasing chemicals should be used. Certified for safety for users, the environment and all device surfaces.

Persons working directly with degreasing chemicals should be fully equipped with labor protection tools. In particular, boots, latex, gloves, clothes, masks…

Users should carefully read the instructions written on the product before use.

Depending on the surface area, the amount of grease to be treated, the user uses the appropriate amount of chemicals. Do not dilute too much because the cleaning effect is not achieved. Also should not be mixed too thick because they cause waste.

Above is some information about industrial degreasing chemicals for you to follow. So you can rest assured to buy these cleaning chemicals and use them for sure, the effectiveness will be very high. Make sure you buy quality degreasing chemicals from major brands in the world and still ensure safety during use.

=>>> Refer to our degreasing products <<<=