The plastic recycling process at companies that collect and recycle plastic scraps is always strictly followed according to the regulations of the Ministry of Natural Resources and Environment. Under the guidance of environmental experts, technology and modern machinery systems.

Plastic recycling is extremely urgent and necessary when 80% of today’s waste is scrap plastic.

The complete plastic recycling process applied today follows the following diagram:

What is recycling?

Recycling is understood as the process of taking materials to be processed to make new products as original by industrial and manual methods such as heating, cooking, pressing, molding, etc.

What is plastic scrap?

Plastic scrap is one of the most popular types of scrap today. It can be mentioned as water bottles, lockers, raincoats, packaging, … These are all very familiar things to us. However, after purchasing plastic scrap, not everyone understands the process of recycling plastic scrap. Follow the following article to have the best view of the recycling process plastic scrap.

How is the recycling process of scrap plastic done?

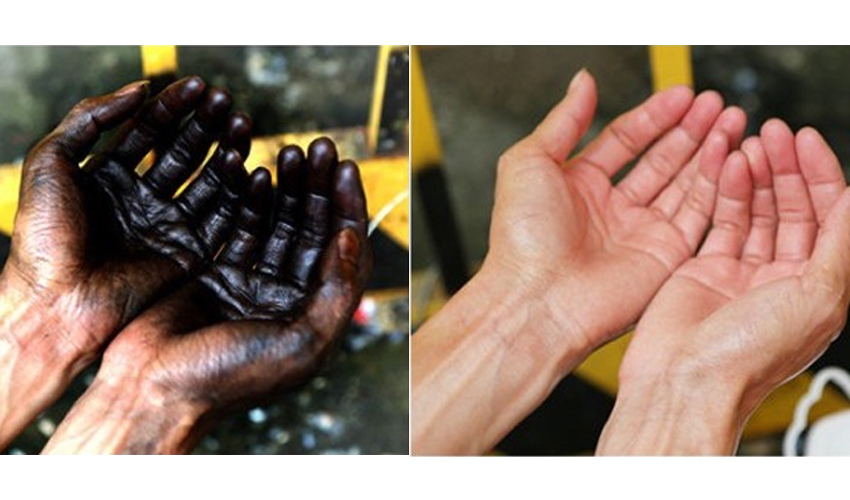

Scrap plastic recycling process: Plastic bottles are screened to remove sand, debris. Then, people use a beam to shine on the bottles to classify them into HDPE, PET or other. Next, the plastic bottles are manually inspected and each type is crushed individually. Scrap plastic and crushed recycling technology are washed in hot water for 1 hour and then the recycled plastic granules will be disinfected, packaged and distributed.

Types of recycled plastic granules today

Recycled plastic granules HDPE, PP, PC/ABS PE, LD+HD, HDPE, PG/ABS, LDPE, ABS, PVC.. mainly currently imported from the following countries: Taiwan, Malaysia, Japan Thai, Arabic…

Sorting plastic scrap? What are recycled plastic products? Recycle plastic bottles?

PVC (polyvinyl chloride)

PVC is also a type of high-density PE plastic commonly used for making ordinary raincoats, plastic boxes, building materials, and plastic products. Although it is cheap and has good ductility, it should not be stored in places with high temperatures. above 81 degrees Celsius.

PVC plastic can release a lot at high temperatures, so it is rarely used for product packaging, cannot be reused and is also very difficult to clean. Although it cannot be reused, companies scrap collection still buy it back to recycle it. In this recycling process, PVC plastic is mixed with a number of additives such as heat stabilizers, various agents: lubricating, plasticizing, UV absorbing, machining aids, hardening, impact resistance, powder. expansion and fire resistance to match the features of each product.

Products of PVC recycled plastic pellets will bring the highest profit among plastic products. You can see the basic recycled plastic products below:

Plastic PE (polyethylene) – PP (polypropylene)

PE plastic is the most common and common type of plastic. In all families, big markets, small markets, supermarkets or roadside shops… the goods delivered to customers are packed in PE bags but are still mistakenly called plastic bags (nylon is a type of polyamide with chemical structure. and completely different properties).

Another plastic close to PE is PP (polypropylene) plastic. PP yarn is also used to weave tarpaulins to cover rain and sun, which is very popular in both urban and rural areas. Because the mechanical properties of PP plastic are higher than that of PE, it is spun and woven into all kinds of packaging containing rice, soybeans, sugar, corn, peanuts, etc. , pots are also usually made of PP plastic. This is considered the best type of plastic.

ABS Plastic (Acrylonitributadiene-styrene)

ABS plastic is used to produce super speed kettle, vacuum cleaner cover, fan cover …

This type of ABS plastic has high heat resistance, good mechanical properties, especially high impact strength, does not know the form when encountering boiling water.

Thanks to the special features of this plastic, plastic scrap collectors also collect and resell to recycling facilities at a fairly stable price to create recycled ABS plastic particles. Recycled ABS plastic granules after being recycled from office machines, injection molding, keyboards, car parts, motorcycles, toys, helmets, light, hard and malleable products such as: tubes, cases, musical instruments, spools, and used to manufacture lower-end products.

PET resin (polyethylene terephthalate resin)

PET plastic is used to produce water bottles in pure water factories with the brands La Vie, Aquafina, Vital… with a capacity of 0.3 liters, 0.5 liters and 1 liter commonly found in households. family, entertainment place and on the reception desk of the office, is a convenient item to carry on business or travel…

This plastic has many advantages as a transparent plastic, which at normal temperatures is not toxic. They can leak into the water, antimony metal and lead oxide are very toxic, especially when hot water is over 70 degrees Celsius or in a high temperature environment. It has good mechanical strength, so it almost does not crack or break during transportation. A large number of PET bottles of different capacities are also used to store foods such as water, vegetable oil, etc.

Scientists have also studied and discovered that this plastic product, if used for more than 10 months, can produce carcinogenic substances. Therefore, we should not reuse plastic bottles made of PET because it is difficult to clean and can contain many types of harmful pathogenic bacteria.

LDPE (low density polyethylene) plastic

It is a low density PE plastic. LDPE plastic is quite popularly used for packaging of instant noodles and confectionery.

This LDPE-containing product will not be able to be heated in a microwave, and should be avoided at high temperatures as it will release chemicals. Therefore, we do not use the microwave to cook instant noodles or foods still in packaging to protect health.

HDPE (high density polyethylene)

This is a type of high density PE plastic – used to store foods for the production of milk bottles, soft drinks and some other liquid foods.

However, the production of HDPE also uses toxic chemicals such as benzene and hexane. Therefore, on the lid of the box, there is always a Braille warning warning not to put it in the microwave. Normally, these HDPE bottles are heat resistant up to 110 degrees Celsius, used to hold food, milk, shower gel or other high purity objects.

All PE, PVC, PET, HDPE ABS plastics belong to the thermoplastic materials family, that is, when the temperature is increased, they soften and then melt and when cooled, they return to their original solid state. Since they are all used for common purposes, they are also called common thermoplastics.

How to cook recycled plastic

To cook recycled plastic, we need to sort the plastic, wash it, and crush it into plastic materials. And the crushed plastic material is poured in batches into the plastic furnace, the hot plastic over 1000C begins to flow out along the paths to the pipe mold (with a diameter of about 2mm-3mm). These pipes will run through a cold water cooling system to shape the plastic wires before being sent to the cutter. At the cutter head, the plastic wire will be cut into pieces with a size of about 2mm, into finished plastic particles that can now be bagged and exported.

>>> Reference: Chemicals to clean PET plastic before recycling <<<