Anti-static is a concept used a lot in life and production. The application of antistatic is applied in many areas such as: Electronic industry, medical, chemical industry,…

So, what is antistatic? What is the operating principle of anti-static flooring? In this article, we will cover the basic knowledge of static electricity, conduction, anti-static, electricity dissipation as well as the operating principles of anti-static floors.

What is antistatic?

First, we need to clarify concepts related to electricity:

- Electricity, also known as charge, is the movement of electrons that occurs on the surface of a material when there is friction, sliding or separation of one material from another.

- Static electricity is the stationary state of electric charge. More clearly, static electricity is the phenomenon of electrical imbalance on the surface of a material. The charge will be stored there until it can be transferred elsewhere through an electric current or discharge.

- A conductive material is one that allows electrons to move across the surface or through most of the material.

- Insulating materials are materials that prevent electric charge from moving completely. Static electricity can store and may even accumulate on the surface of these materials.

- Antistatic materials are materials that help release electrical charges and prevent them from building up.

- Electro dissipative materials are materials whose surface static electricity is dissipated.

So, Antistatic can be understood as the use of measures to minimize the accumulation of charge on the surface, thereby minimizing electrical discharge.

How does electrostatic discharge impact industries?

Electrostatic discharge can weaken or destroy fragile electronic circuits. In fact, it has been proven that: Some electronic components can be damaged by an electric discharge of about 300V, while just one person passing by at once can create a current of up to 3000V.

So to prevent that damage, facilities operating in the electronics field must install anti-static floors as part of limiting electrostatic discharge. In addition, to ensure there is absolutely no electrostatic discharge, the above facilities must be accompanied by other elements such as: Clothes, shoes, bracelets, grounding,…

Electrostatic discharge occurs a lot in places with sensitive electronic equipment, to name a few as follows:

- Healthcare industry

- Aviation

- Ammunition industry.

- Electronics and electronic components manufacturing industry

Application of antistatic flooring

December 2021 – ESDA issued standard ANSI/ESD S20.20-2021 – standard on electrostatic discharge management, applicable to all organizations, areas, production, assembly, transportation, testing,… devices with electrostatic discharge greater than or equal to 100 volts HBM (Human Body Model – discharge model from the human body) and 200 volts CDM (Charged Device Model – discharge model due to broken components). electrically charged) or conductive devices with a voltage below 35 volts.

Operating principle of anti-static floor

Anti-static flooring helps ground employees as they move around within the work area, preventing the build-up of harmful static charges. (correct this sentence)

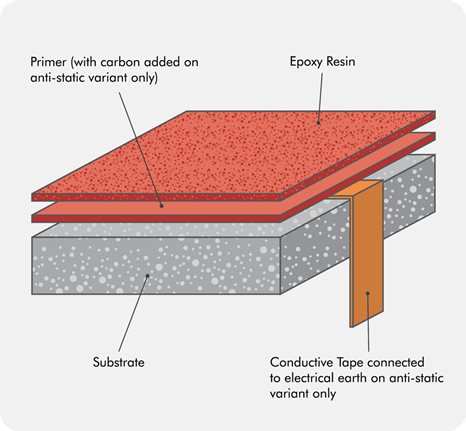

There are many types of anti-static floors such as PVC, Epoxy, Vinyl floors, etc. Each type has a different advantage, depending on the factory conditions chosen. Anti-static vinyl flooring is the type of flooring that is most trusted and used.

Vinyl flooring is a high-end form of PVC flooring, made of 4 layers pressed tightly together:

1st layer is the surface layer, or layer, made from transparent synthetic plastic and aluminum acid, which is waterproof as well as anti-fouling, limiting scratches.

2nd layer is the printing layer, designed to bring decorative patterns, colors,… to satisfy user tastes.

3rd layer is the underlayment layer, with a layered foam structure, providing elasticity and toughness to the floor. (correct this sentence – layer foam)

The last layer is the base layer which is the skeleton of the floor, creating the floor’s rigidity, maintaining balance as well as stability for the PVC bars when attached to the floor.

In anti-static vinyl floors, conductive compounds are used to guide charged particles through the carbon circuits between the layers of the floor surface and down to the conductive adhesive layer below, from this adhesive layer, the electrical particles The charge is conducted through a small copper wire to the ground or a conductive material such as a steel pole, thereby eliminating the phenomenon of conduction.

Anti-static floor surface layers

In addition to using anti-static materials, we can also use anti-static floor coating product Q-GLOSS ANTISTAT to further increase anti-static properties. The product creates an anti-static, colorless, glossy layer and protects hard, resilient floor surfaces, including marble, granite, wood and cement. Especially suitable for vinyl and epoxy material floors.

The protective layer is highly durable, safe from chemicals and scratch resistant. The surface after coating is easy to clean and maintain.

See more about the product: Q-GLOSS ANTISTAT

Method for measuring antistatic index

Antistatic index is an index showing the antistatic ability of a material, which can be measured by resistance. The higher the resistance, the lower the antistatic ability and vice versa.

There are many different methods of measuring resistance. Particularly when measuring surface resistance, it is necessary to follow BS EN 61340-5-1 standard. This method is a popular choice in many countries. Check the conductivity of each point in detail, using a meter to measure the resistance level between two fixed points on the floor.

Through the measurement results, determine whether the floor surface can be classified as conductive, insulating or dissipative.

| Class | Resistance (Ohm) | Antistatic |

| Conduction | 103 – 105 | Yes |

| Dissipation | 106 – 1010 | Yes |

| Insulation | >1011 | No |

(Classification table of antistatic materials according to standards of EIA – Electronic Industries Alliance, electronic business alliance)

See more: https://esdsystems.com/whitepapers/wp_standards.html